- The highest stresses in the support box occur at the joining and

attachment points, where loads and moments are transferred into and out of the component.

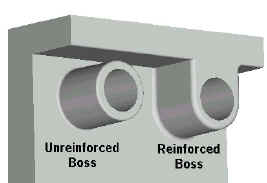

- The uplock support has numerous flanges, ribs, lugs, bosses,

grommets, and stand-offs for strength and assembly purposes.

- One of the benefits of casting is the design flexibility to

reinforce section thickness at high stress areas where improved strength and stiffness are

desired.

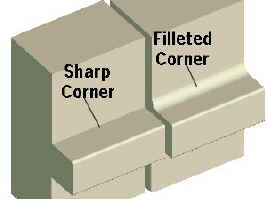

- In addition, the generous fillets designed into and produced in

castings reduce/eliminate the stress concentrations found at joints between sections.

|

Example of Reinforced Boss

|

Example of Fillet

|

|