The customer

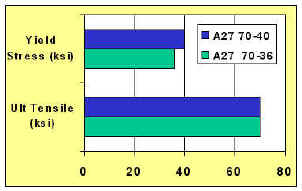

originally requested an A27 70-36 steel alloy.

- A27 (70-36) has a maximum of 0.35%

carbon and 0.70% manganese with an ultimate tensile strength of 70 ksi and a yield

strength of 36 ksi.

Atchison Engineers suggested an A27 70-40 steel alloy with a

higher yield strength.

- A27 (70-40) has a maximum of 0.25%

carbon and 1.20% manganese with an ultimate tensile strength of 70 ksi and a yield

strength of 40 ksi.

|

Comparison of A 27 70-36 and 70-40

|

|