|

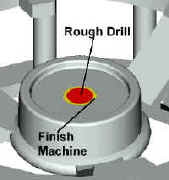

| Two

Step Machine |

|

| Center

Core & Machine |

|

Casting

is a near-net shape process, and the casting design engineer almost always

has

the option of producing a feature on the component with a

feature in the mold.

One

of the key features in the drive wheel is the center bore in the hub for

the drive shaft. This hole has precise dimensional tolerances on the ID

along with a keyway.

The casting

designer had two choices in producing this center bore.

|