|

|

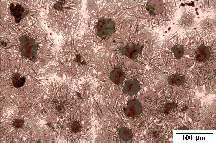

Austempered

Ductile Iron Microstructure -- Austenitized 950°C, austempered 350°C

for 64 min

|

|

But

a specific type of cast iron (austempered ductile iron - ADI) offers performance

and cost advantages that need to be considered.

The term

"cast iron" designates an entire family of metals with a wide

variety of properties. Cast iron contains more than 2% carbon, present as

a distinct graphite phase.

In ductile

cast iron the graphite occurs as spheroids or spherulites rather than as individual flakes as in gray iron.

Ductile iron exhibits a linear stress-strain relation, a considerable range of yield strengths, and, as its name implies, ductility.

|

|

"Austempering" is a high

performance heat treatment for ferrous alloys which produces an

engineered, tailorable matrix structure.

This austempered matrix structure gives tensile strength,

toughness, impact strength and fatigue properties that are comparable to

heat-treated steels.

|