| Initial

Casting Decisions Before detailed design

and manufacturing decisions are made, the casting designer has to consider two fundamental

issues --

- What is the most appropriate casting process?

- What is the most appropriate alloy to use in the

casting, considering both the performance and the manufacturability (castability and

machinability)?

Go to the

casting process and alloy selection pages.

|

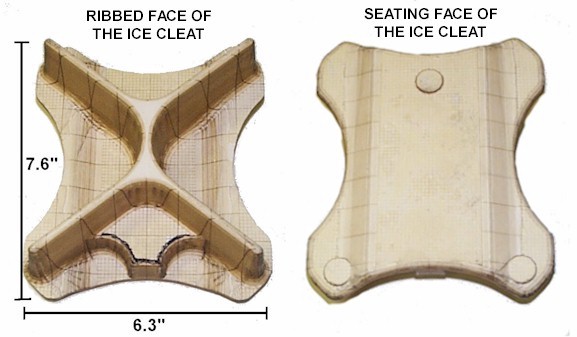

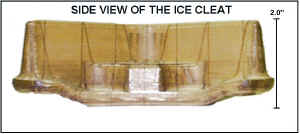

Model of the Ice Cleat made by

Laminated Object Manufacturing

|

| Detailed

Design Factors Once the casting process

and the alloy are selected, the casting designer carefully reviews the component, looking

at the factors and design features that determine soundness and castability.

- Draft Angles, Radii, and Fillets

- Hot Spots and Thin Sections

- Directional Solidification

- Parting Line and Orientation

- Risers for Metal Feed

- Gates and Runners

Go to the

detailed casting design pages. |

Model of the Ice Cleat made by

Laminated Object Manufacturing

|