-

The

center bore in the hub is finished taper bored to the final dimensions.

A

key slot is cut into the center bore of the hub section.

-

The

center bores in the forks are finished

bored to the final dimensions with a step for a bearing seat.

-

The

outer faces of the forks and the heavy hub are finish milled flat.

-

Two

bolt holes (~1" diameter, 2" deep) are drilled and tapped

into the main hub, for attaching a cover plate.

|

|

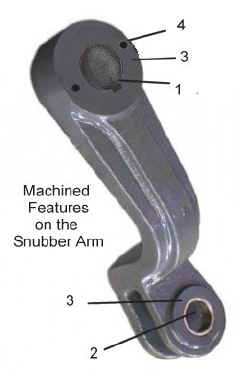

| Snubber

Arm Finish Machined. |

|