Machine Pintle Socket Bowl

|

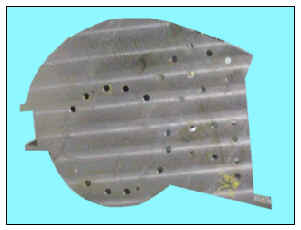

Machined Top Plate |

|

After solidification is

complete, the casting is -

- Removed from the flask and cleaned of sand in the

shake-out process.

- Surface cleaned by shot blasting.

- Cut and trimmed to remove the rigging and the

risers.

- Heat treated with a normalization and a tempering.

- Finish cleaned and trimmed by grinding.

- Visually inspected and evaluated by ultrasonics.

- Quality checked for dimensions.

- Sent out for rough and finish machining.

|