- Proper design of the rigging system is critical to provide

for uniform, controlled metal flow into the mold.

==> Non-uniform, long path, and/or slow metal flow may produce unfilled

sections or solidification shrinkage in the casting.

==> Excessively rapid metal flow or metal

splashing will cause mold/core erosion and oxidation of the steel, producing non-metallic

inclusions in the casting.

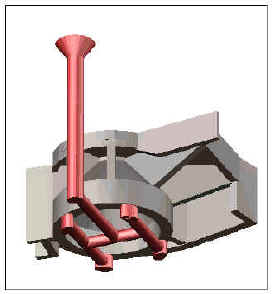

- The pintle socket casting is rigged with a side sprue

connected to four runners feeding into four ingates located around the base of the large

bowl.

==> The rigging is

illustrated in the drawing to the right.

|

Rigging System for the Pintle Socket

|

|