|

Component

in Plasma Nitriding

Chamber

(from Rubig Plant Technology) |

|

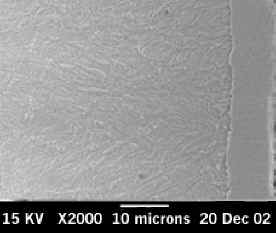

| Microstructure

of Nitrided

Surface Layer (to the right) |

|

The

wear resistance and durability of the lever arm are enhanced by a

plasma nitridation which develops a hard surface layer on the entire

component.

-

Plasma

nitriding (also known as ion nitriding) is a low temperature, low

distortion surface engineering process.

-

A

D.C discharge plasma is used to transfer nitrogen to the surface of

the components at temperatures between 400°C and 750°C at low gas pressures.

-

The

nitriding process produces a nitride rich surface layer with high

surface hardness and hardened depths up to 0.8mm with minimal high

temperature distortion of the component.

|