|

Conventional

gravity casting poses several shortcomings in producing the

lever arms.

-

In gravity casting, solidified

metal in the down sprue dramatically increases alloy usage and cost,

compared to CLA.

-

Variability (from one

pour to the next) of metal flow into the mold cavities makes reliable

casting fill-out difficult.

-

Metal flow is much more

turbulent, increasing the chance for trapped gas and oxide inclusions.

|

|

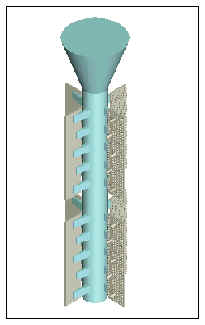

Conventional gravity casting with sprue and down spout that need

to be removed

|

|