What is the Most Effective Casting Method? |

| Critical Requirements for the Ice Cleat The ice cleat has the following performance and production

characteristics which have an impact on the mold type--

- Tolerances are +/- 0.06" with moderate surface

finish

- Fast first item delivery with low rate, long term production

- Component design has moderate complexity.

- Choice of molding method can be a major factor in production cost

|

Casting

Mold Options: The casting can be produced by

3 different types of molds: |

|

|

|

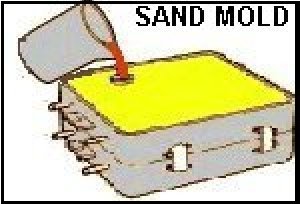

| Green Sand Mold -- Made by packing loose sand around a

pattern and removing the pattern to form a hollow mold. |

Investment Mold -- Made

by making a wax pattern in a metal tool and then coating

the disposable wax pattern with refractory coating and melting out the wax. |

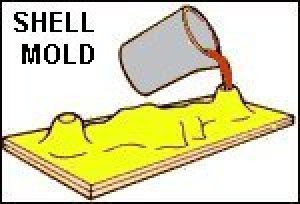

Shell Mold -- Made by heating a resin-sand mixture in metal

tools, forming top and bottom shells which are joined to form

a mold. |

Given the following characteristics of the 3 molding methods,

choose the mold type

that is most appropriate for producing the ice

cleat. |