As-Cast Case

|

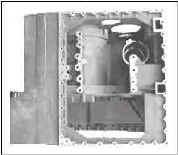

Machined Case

|

|

The machining of the transmission case was extensive --

--- Milling of faces and

mating surfaces.

--- Boring of access holes.

--- Drilling and tapping of screw holes.

The transmission case was machined by Schwartz

Industries of Warren, MI.

--- Diamond tooling was used

for face milling.

--- Proprietary diamond tipped carbide tools

were used boring and drilling.

--- Solid carbide roll form taps were used for

tapping the M8, M10, and M14 holes.

--- A total of 41 unique tools were required to

machine this casting.

--- The machining engineer estimates that the

part can be machined with only a 110%

increase in machining time, compared to

standard aluminum. |