Mold

Design and Part Orientation |

In mold

design for gravity casting, the orientation of the part in the mold is an important factor

in producing a sound metal matrix composite casting.

- Casting defects, when they occur in SiC- aluminum,

favor the cope or upper surface of gravity castings.

- Primary surfaces should be designed so that they are

molded in the drag or the lower section of the casting.

- Additional machine stock should be allowed on uppers

surfaces to that surface defects can be removed if necessary.

|

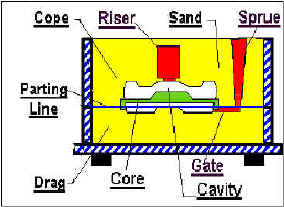

Cope and Drag Mold Geometries Showing Low Parting LIne

|

|

- Placement of the parting line is critical in casting

SiC-aluminum.

The metal feed runners

and gates are in the top section of the lower drag mold. The molten metal should enter at

the bottom of the mold cavity, minimizing metal fall.

Therefore, the mold

cavity should sit high in the mold, with the parting line at the bottom of the mold

cavity.

|

|

|