- Story of the Steel Casting Design Pathway

Target Audience: OEM Casting Designers & Buyers, Steel Casting ProducersThis is the introduction to the entire SFSA webinar series “Steel Casting Design & Manufacturing Engineering.”The series is presented in the context of a story: How Michael Gwyn, career-long SFSA member and 25-year steel

casting producer, discovered innovative principles for excellence in steel casting design. Webinar 1 is glimpse

into his “Trail Map” for both design geometry and resulting producibility.

View the Story of the Steel Casting Design Pathway - Steel Casting Geometry: Freeway to Producer Response

Target Audience: OEM Casting Designers & Buyers, Steel Casting ProducersThis is an overview of the principles of excellence in steel casting design geometry with the benefits that flow down from geometry excellence, through the producer, to better prices and shorter lead-times. Conversely, the consequences of the typical “fair-to-poor” design geometry flow through the producer’s tooling design, mold process engineering, and finishing operations… all at higher cost.

View Steel Casting Geometry: Freeway to Producer Response - Castability Geometry

Target Audience: OEM Casting Designers, Steel Casting Producer Technical Sales & MarketingThis episode in the SFSA Casting Design & Manufacturing Engineering webinar series is foundational. A critical distinction is made between the age-old concept of “Alloy Castability” and the discovery that CASTING GEOMETRY enables whatever “Alloy Castability” exists to be accommodated. In other words, and especially for steel casting alloys, the concept of CASTABILITY GEOMETRY enables even an alloy with poor castability to “LIKE” the mold cavity geometry that it flows into and solidifies. This discovery is critical to OEM casting designers.

View Castability Geometry - Castability Geometry Differs by Steel Alloy Type – Parallel Pathways

Target Audience:OEM Casting Designers, Steel Casting Producer Technical Sales & MarketingWhile SFSA Webinar 3 is foundational for the entire “Informational” and “More Depth” series, this episode is nearly a twin. The baseline for Castability Geometry is the family of Carbon & Low Alloy steels made in room temperature sand or ceramic molds; Deviating from that baseline in varying degrees are the High Alloy steels. Those deviations are grouped among the High Alloy steels in this episode, and how to modify Castability Geometry for each High Alloy group is shown in models and simulations.

View Castability Geometry Differs by Steel Alloy Type – Parallel Pathways - Interior Mold Cavity Geometry Junctions – A Pathway Entanglement

Target Audience: OEM Casting Designers, Steel Casting Producer Technical Sales & Marketing, Producer Foundry EngineersEpisode 5 in the SFSA Casting Design & Manufacturing Engineering webinar series addresses the problems and solutions for thickness differences in the mold cavity interior regions. Interior thickness differences result from junctions of shapes. An example would be a wall from the casting’s exterior joining a cylindrical boss in the middle of the mold cavity. Sometimes the thicker section is functional, like a boss for a fastener or bearing. Often it is increased thickness for resisting stress structurally.If a junction with more thickness occurs along the perimeter of a steel casting design, there is no problem. A riser can easily be attached to the perimeter to feed the additional thickness. However, in the mold’s interior, feeding that thickness is not so easy. How to resolve that difficulty in both the OEM’s design geometry and the producer’s tooling design is our subject, and it is necessary for successful Castability Geometry. And… how to do so for steel alloy sub-groups whose Castabilty Geometry parameters are different.

View Interior Mold Cavity Geometry Junctions – A Pathway Entanglement - Process-Dominated Castability Geometry – A Fork in the Pathway

Target Audience: OEM Casting Designers, Steel Casting Producer Technical Sales & Marketing, Producer Foundry EngineersThe production of steel castings is dominated by room temperature molds, primarily in sand mold cavity-making processes. Castability Geometry for those mold types has been well-defined in episodes 3, 4, and 5. However, a very significant sub-set of steel castings are poured in hot ceramic shell investment molds. This episode 6 addresses the differences in OEM Castability Geometry choices in design AND producer manufacturing engineering principles for the three steel alloy sub-groups… when produced as investment castings in hot molds.Steel casting producers in the hot ceramic shell process typically pour a wide variety of ferrous alloys. Process-Dominated Castability Geometry explains why. Design and manufacturing engineering principles for hot ceramic shell molds are illustrated in models and simulations.

View Process-Dominated Castability Geometry – A Fork in the Pathway - Welded Steel Fabrications: A Dead-End Side Track

Target Audience: OEM Casting Designers, Steel Casting Producer Technical Sales & MarketingThis webinar episode is a highly visual “peek under the design engineer’s tent” revealing the reasons for and consequences of fabricating structural components by welding wrought steel pieces together. And… why, after all has been invested in the fabricated design, there is almost always a significant return on investment when starting all over with a casting design.Conversion of fabrications to castings is a large market segment dominated by ductile iron casting conversions… and that is good for all concerned. But… when the combination of high stress, allowing deflection, long cyclic life, and low mass is the requirement, steel castings are unsurpassed.Why steel castings dominate, when capability is really important, is explained with simple metallurgical and structural design reasons…. and a case study. The case study is a capstone for Episodes 1 through 5, showing how Castability Geometry in steel casting design works. And, a glimpse of a future episode explaining the overlay of Structural Geometry on the Castability Geometry foundation.

View Welded Steel Fabrications: A Dead-End Side Track - Net Shapes Machined from Wrought Steel: A Shortcut to the Dead-End Side Track

Target Audience: OEM Casting Designers, Steel Casting Producer Technical Sales & MarketingA second alternative to steel casting design, aside from welded steel fabrications, is forming a component’s final net shape entirely by machining. The material is a wrought block, bar, or forged pre-form of steel… actually any metal, because this design alternative is not just for steel castings.Today’s CNC machining centers with multi-axis tool paths combined with multi-axis fixture pallet movements can whittle out virtually any net shape with the exception of shapes having complex, narrow, curved interior passageways.Fully machined from wrought stock is a design alternative especially attractive for military and aerospace components. Mechanical properties are known with high certainty, prototyping is easy to match with production reality, prototypes have very high probability of successful high cycle durability testing, and tooling up, getting through prototyping, testing, and into production is usually quickest.So, why is it the “shortcut to the dead-end side track?” The answer is the high cost of fully machined production components. Being quick and capable was great, but the reality of lots of chips at the bottom of the machining center and not much net shape becomes a cost problem.Why to choose NOT to get stuck in the first place is our subject in Webinar 8. Our target audience is OEM design engineers. In addition to the details of “why NOT take the shortcut,” there are two short, helpful “main-line tracks” for design engineers: 1) Why manufacturing engineering of a casting design… by the OEM Design Team… at the early design stage, is very powerful, and 2) Why to-scale, proportional, isometric pencil sketches are very efficient starting points for casting solid models… and HOW to make them.

View Net Shapes Machined from Wrought Steel: A Shortcut to the Dead-End Side Track - Steel Casting Gating Principles: Temperature Distribution for Solidification Integrity plus Reoxidation Inclusion Control

Gating of castings is a very “metal caster-specific” subject among all casting alloys and all mold cavity-making processes, and personal opinions abound. Since steel castings, across all of its alloys and processes, are especially difficult to produce, manufacturing engineering of gating is a very “near and dear” skill set. So, gating is a special arrow in a steel casting producer’s quiver that enables a difficult design to be produced to specifications.Regardless of personal preferences for specific gating geometry, runner and in-gate sizing and ratios, pressurized systems or unpressurized, and filters/no filters, there are 5 fundamentals of physics that are involved in gating effectiveness that transcend those more personal preferences. The 5 fundamentals also apply equally well among all the steel casting alloys and among all the mold cavity-making processes, including the investment process.

View Gating Principles: Temperature Distribution for Solidification Integrity plus Reoxidation Inclusion Control - Risering Principles for the 3 Steel Casting Alloy Sub-Groups

This episode constitutes Part 2 in the set of 2 that addresses the manufacturing engineering of steel casting mechanical properties, cosmetic appearance, and mitigation of reoxidation inclusions. Specifically, the 2 parts are Webinar 9, Gating, and this Webinar 10, Risering. The two webinars address all of the fundamental principles in the manufacturing engineering of a steel casting mold cavity that work together to maximize the most important capabilities of steel castings… and, at their maximum, the best of all metalcastings in structural capability.

Gating of steel castings has 5 necessary fundamentals from physics that govern successful design, but there is latitude for steel casting producers’ personal preferences. Not so for risering of steel castings, which is very rule-driven and narrow when designed to maximize mechanical properties and cyclic life.

“Risering” (quotes intentional) of steel castings is a system, an orchestrated spectrum, of multiple facets. This episode defines and illustrates all the facets in that spectrum. Across the 3 steel casting alloy sub-groups and between the two major mold-making processes (sand and investment), there is consistency in the major “Risering” requirements. But, there is some important variation among the 3 sub-groups’ differences and the process’s differences.

View Risering Principles for the 3 Steel Casting Alloy Sub-Groups - Prototyping New Steel Casting Designs: What to Accomplish and Why?

This episode is Part 1 of a 2-Part series addressing a steel casting producer’s challenge of launching new business… the launch of a customer’s new design. These two episodes profess the rarely used, but undeniably efficient use of “Immediate Prototyping.”

In the zeal to realize the new business from a new design’s launch, it is tempting to assume a new steel casting is similar to what is done every day… business as usual. But, business as usual today came with a lot of grief, cost, and delays yesterday, and those difficulties have faded from memory over time.

Instead, tooling up quickly and temporarily for “Immediate Prototypes” with today’s solid model-based technologies enables discovery of all the new casting’s manufacturing issues. Then, those issues don’t get wrapped up in production tooling that was built too soon and expensive and time-consuming to fix.

The next episode, Webinar 12, explains how existing and emerging Subtractive and Additive Manufacturing technologies enable the “quick” and enable the manufacturing engineering insights that underlie an on-time, cost-effective, new steel casting production launch.

View Prototyping New Steel Casting Designs: What to Accomplish and Why? - Prototyping New Steel Casting Designs; Part 2: The Power of Additive Manufacturing to Enable Prototyping Quickly

This episode is Part 2 of a 2-Part series addressing a steel casting producer’s challenge of launching new business… the launch of a customer’s new design. Part 1 addressed the “Why” of the rarely used, but undeniably efficient use of “Immediate Prototyping.”

Part 2 addresses the need for and ability of “Immediate” when applying the power of Additive (and Subtractive) Manufacturing processes. Because of the continuing expansion of the breadth and depth of Additive Manufacturing processes and materials, “Immediate” really is not confined to prototype tooling. Rather, and even more powerfully, the capability has become “Immediate Prototype Mold Cavities.” After all, it is the steel casting prototype mold cavity, whether made in sand or investment ceramic, that is needed quickly and that can be revised quickly.

This Episode 12 includes a brief overview of the Additive and Subtractive processes directly applicable to making “Immediate Prototype Mold Cavities,” including examples of how dimensional and solidification integrity compliance can be accomplished quicker and more reliably. There is a concluding segment explaining how “Immediate Prototyping” can demonstrate capability in producing more as-cast surfaces in final steel casting net shape. More net shape as-cast surfaces and less machining can enable a steel casting producer to be more price competitive while retaining better margins.

View Prototyping New Steel Casting Designs; Part 2: The Power of Additive Manufacturing to Enable Prototyping Quickly - Structural Geometry Overlay on Steel Castability Geometry Part I – Is Cast Steel Really Steel?

This episode is Part 1 of a 2-Part series addressing structural design of steel castings, especially the largely untapped capability of steel castings to achieve lower-than-expected mass while sustaining their long cyclic life capability. Fundamental in this entire SFSA webinar series on Steel Casting Design and Manufacturing Engineering is the principle of Castability Geometry. Castability Geometry enables any alloy among the 3 steel casting alloy sub-groups to “like” the mold cavity geometry that it flows into. That compatibility between alloy characteristics and the steel casting design shape enables much easier producibility of surface and microstructural integrity.

Control of a load case with specified mechanical properties and intended cyclic life is accomplished with Structural Geometry. Logically, Structural Geometry must be compatible with and overlaid upon Castability Geometry.

“Quality Detail” is a term coined by SFSA to express the idea of casting imperfections that are not necessarily surface or solidification integrity non-conformances. This Part 1 addresses a design and durability analysis engineers question, “Is cast steel really steel as I know it in wrought forms?” The answer is “Yes,” and Part 1 demonstrates “really steel” with data and steel casting durability examples from the author’s own steel casting design and production experience.

View Structural Geometry Overlay on Steel Castability Geometry Part I – Is Cast Steel Really Steel? - Structural Geometry Overlay on Steel Castability Geometry Part 2 – Long Cyclic Life Integrated with Low Mass

Structural Geometry for castings in general, and certainly structural steel castings, must be overlaid on the foundation of Castability Geometry. Castability Geometry, its necessity and its principles, was defined in Webinars 3, 4, 5, and 6 of this series. If Structural Geometry is built without Castability Geometry or if it is overlaid on Castability Geometry without specific engineering mechanics principles, solidification integrity will be damaged. Insufficient solidification integrity cannot sustain a steel casting’s specified mechanical properties.

In the first of 3 Segments, the engineering mechanics of structure is defined in a way that sustains solidification integrity from Castability Geometry and supports the load case efficiently.

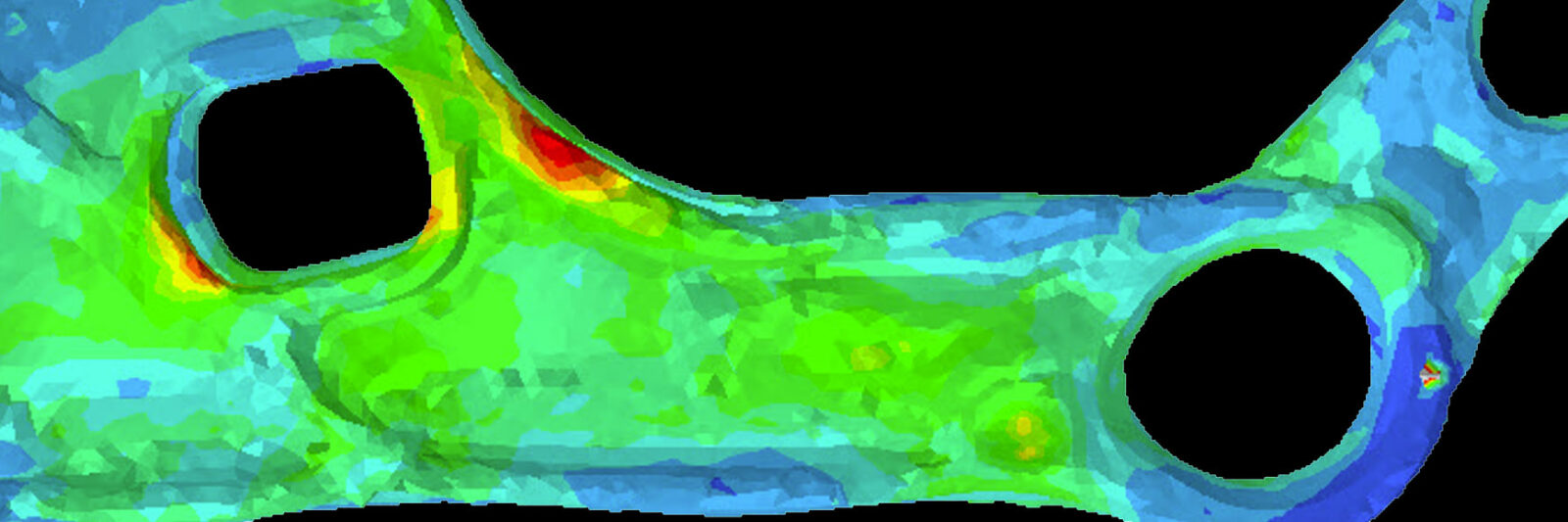

In the second Segment, fracture mechanics is used to determine how much von Mises stress can be allowed in the design to sustain the casting’s intended cyclic life. Fracture Toughness, as a facet of fracture mechanics, uniquely enables the complexity of potential Quality Details at the surface or near surface of critical load case steel casting cross-sections to be simplified. Finding allowable von Mises stress data for all the complexities of load cases and Quality Details is almost impossible for castings… and more so for steel castings. Fracture Toughness can transcend that near impossibility.

The third Segment is an epilogue for viewers interested in why Fracture Toughness is so powerful in steel casting design. The epilogue bores into the details of how Fracture Toughness is measured, and how a specific value of Fracture Toughness, K1C is measured and defined as a material property for a wide variety of steel casting alloys.

View Structural Geometry Overlay on Steel Castability Geometry Part 2 – Long Cyclic Life Integrated with Low Mass