Table of Contents

79th Technical & Operating Conference and Workshop

Supported by steel foundry members that make up the Society, the T&O conference is the premiere steel casting event in the world. The 79th conference will continue the legacy of technical and operating topics of today that will provide value to the industry for many years to come. This year’s workshop program will feature presentations on gas, technology road mapping, continuous improvement, industry 4.0 and lean manufacturing. The conference program covers everything from melting to foundry engineering to molding to finishing to management to EHS to quality to technical & featured research. For assistance with registration, please contact Renee.

Industry 4.0 Webinars

SFSA is planning two Industry 4.0 member webinars: Automation & AI for Steel Casting Manufacturing Steps and OT Security.

Automation & AI will be a half hour presentation on the process for using these and then a half hour with members discussing steps in manufacturing castings that are of interest.

OT security will bring forward concerns and considerations as foundries continue to use and exchange Operational Technology data. Additional details and a link for the seminars will be emailed to members in the near future.

Please contact Dave with any questions.

Subject-focused Meeting Resources

Did you know, a number of SFSA presentations from past subject-focused meetings are available to members? Some popular recordings include Section IX welding, quenching and Artificial Intelligence (AI). Several of the presentations from the recent Riser Sleeves and Segregation meeting are now posted to the wiki. Whether you were not able to attend a meeting, joined your foundry after the meeting, or maybe have taken on a new job role, these videos bring forward the content as a resource for members.

Specification Committee

SFSA is actively involved in American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO), Boiler and Pressure Vessel Code (BPVC), and American Welding Standard (AWS). The specification bodies foster collaborative development of commercial standards, which SFSA will work with to transition technologies into new or existing standards. These efforts are led by our Specification Committee, which will meet on November 11th in Atlanta, GA. For more information, please contact Dave.

Cast in Steel Competition

We already have ten teams signed up to recreate a replica of a Horseman Axe for the upcoming Cast in Steel Competition, taking place in Grand Rapids, Michigan, April 16–18, 2026!

| UNIVERSITIES | FOUNDRIES |

|---|---|

| California State Polytechnic University – Pomona | Miller Foundry |

| Pittsburg State University | Monette Metals |

| ESFF-Ecole Superieure de Fonderie et de Forge | Ferry-Capitain |

| Ecole Nationale Supérieure D'Arts Et Métiers Campus de Cluny | Safe Metal |

| Central Michigan University (2 teams) | Bay Cast Inc |

| Ferris State University | Eagle Alloy, Inc. |

| Kevin Dukes Career and Innovation Academy | In contact |

| University of Northern Iowa | UNI Metal Casting Center and Factory 4.0 Center |

| Wentworth Institute of Technology | DW Clark |

Raymond and our judges have put together some fantastic podcast episodes to help students with their Axe projects. Whether you’re looking for practical tips, creative ideas, or just want to learn more — these are definitely worth a listen! You can find all the episodes on the competition link below.

If your foundry is interested in partnering with a team to cast their axe for the 2026 competition, please reach out to Renee rmueller@sfsa.org.

For full competition details, click HERE.

Casting Dreams Competition

The 2026 Casting Dreams season is off to a strong start with seven events already scheduled, and more being added.

If you’re interested in hosting an event or sponsoring (through donations or materials), we’d love to hear from you!

Reach out to Renee Mueller at rmueller@sfsa.org with any questions or to get started.

Let’s keep the momentum going!

Check out the upcoming events below.

| DATE | LOCATION | EVENT NAME |

|---|---|---|

| 7-Feb-26 | Crystal Lake, IL | McHenry Community College -Casting Dream Workshop |

| 15-Nov-25 | Johnstown, PA | National Center for Defense Manufacturing & Machining-Casting Dreams Workshop |

| TBD | TBD | FEF High School Outreach |

| TBD | San Luis Obispo, CA | Casting Dreams Workshop |

| 4-Oct-25 | Crystal Lake, IL | McHenry Community College -Casting Dream Workshop |

| September 26-27, 2025 | Birch Run, MI | Frankenmuth Arts Festival -Casting Dream Workshop |

| July 21-24, 2025 | Romeoville, IL | Fabricating the Future |

| 26-Jun-25 | Woodstock, MD | Casting Dream Workshop |

| June 9-12, 2025 | Romeoville, IL | Fabricating the Future |

| 12-Jun-25 | Crystal Lake, IL | Twilight Camp - Girl Scouts |

New Member Program – MSC Industrial Supply Co.

SFSA established a new program for members which qualifies them for exclusive benefits, discounted pricing, unrivaled service, and unparalleled technology when working with MSC!

The SFSA MSC Program brings members significant discounts and access to MSC’s catalog of manufacturing services, enhancements and specialists.

Program Highlights

- Access to 2.4 million industrial SKUs

- Access to the most robust offering of metalworking products

- Same-Day Shipping with 99% fill rate

- Free Freight on your orders

- Optimized Inventory Management Program

Product Line Discounts

| Product Line | Discount |

|---|---|

| Abrasives | 12% |

| Carbide Indexable | 12% |

| Cutting Blades | 12% |

| Drills and Reamers | 12% |

| HSS End Mills & Cutters | 12% |

| Taps & Dies | 12% |

| Hand Tools | 10% |

| Janitorial | 12% |

| Power Tools | 8% |

| Safety (PPE) | 12% |

| Fasteners | 20% |

| Material Handling | 10% |

How to Enroll

To get started, fill out and sign the MSC-SFSA Program Affiliation Form and email it to rmoore@sfsa.org.

If you have questions or need more information, contact Ryan Moore at (815) 455-7851 or rmoore@sfsa.org.

Trade Resources

Tariffs were a central topic at this year’s Fall Leadership Meeting. The program included an informative presentation by Dan Pickard, a trade attorney with Buchanan and experienced working with the steel casting industry. Dan covered some trade resources available to SFSA members which include:

- An e-newsletter that provides updates on tariff developments nearly every week. To subscribe, go to https://buchananpm.concep.com/preferences/buchananpm/signup and click the box next to ‘International Trade & National Security’.

- The next opportunity to submit derivative products to the 232 is January 2026. The BIS website outlines the Section 232 Steel and Aluminum tariffs and the process for submitting derivative product inclusion requests. In addition, the BIS Federal Register notice from May 2025 provides additional details on the information required for inclusion requests. For questions regarding provisions in this rule specific to steel inclusion, contact Stephen Astle at 202-482-2533, or email Steel232@bis.doc.gov. For assistance with submitting an inclusion request, contact Dan Pickard – Daniel.pickard@bipc.com.

Market News

ITR reports that the release of August new orders data is delayed due to the U.S. government shutdown, but forecasts remain based on leading indicators and economic fundamentals. Updated production data shows continued upward momentum into 2026 despite uneven sector performance. Defense and tech remain areas of opportunity, while heavy-duty truck production is a laggard.

SFSA 2026 Market Forecast

To see what may lie ahead for next year, the SFSA 2026 Market Forecast, presented last month at the SFSA Fall Leadership Meeting, is now available online here.

SFSA Business Trends

To benchmark your facility with other steel foundry members, SFSA encourages you to participate in the monthly SFSA business trends survey – only participants have access to the results. The quarterly data will no longer be included in the Casteel Reporter. Please complete the business trends survey for September 2025: https://www.surveymonkey.com/r/SFSA_BTB_Sep25. Survey results are provided to participants the following month.

SFSA Business Report

Due to the government shutdown, August data is not available from the Department of Commerce. An updated business report will be published in the November Casteel Reporter.

Casteel Commentary

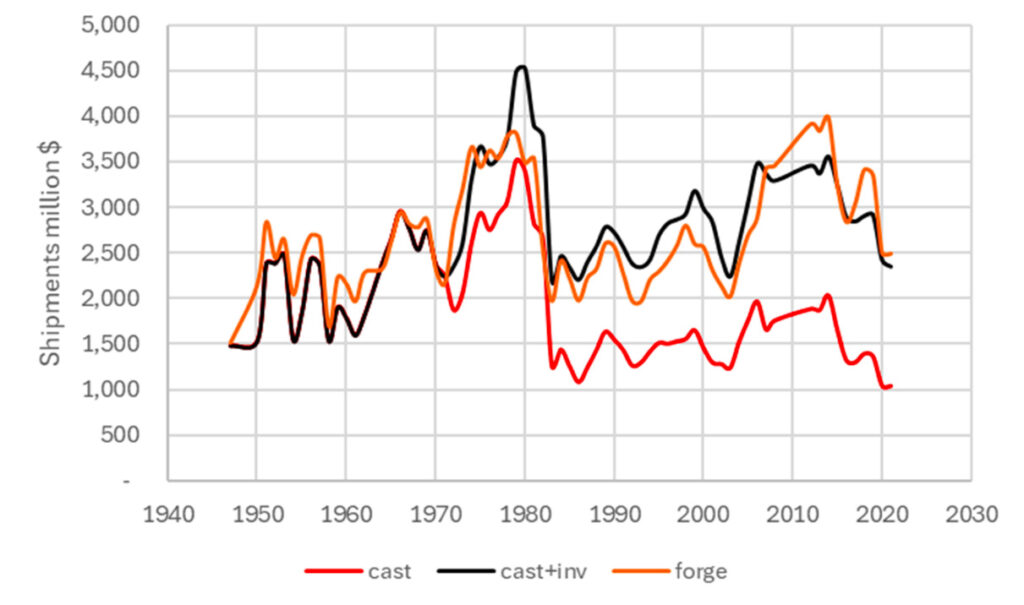

To make the case for changes needed by our industry to remain a robust supplier for the needs of North America, producers of steel castings need a commercial framework that allows profitability. Our industry has been under pressure since 1980 after supporting the prior defense and infrastructure requirements. The values of casting and forging shipments for the U.S. are seen in Figure 1.

The dramatic drop post 1980 is seen in the continuing low level of steel castings shipments. The iron and steel forging industry had less of a drop and has seen some recovery. One factor for the drop in shipments is the completion of much of the basic infrastructure needed. Another factor is the loss of market, not so much from direct imports but due to the loss of markets for our customers globally. Their competitors also took market share in North America. The recovery of the forging industry that is more significant than for our steel castings depended significantly their products which are tied to consumer goods and to their significant participation in the aerospace and defense industry. Those segments do require steel castings, but they are made principally as investment castings. If the steel investment casting shipments are added to our shipments, our market values match closely to the forging industry.

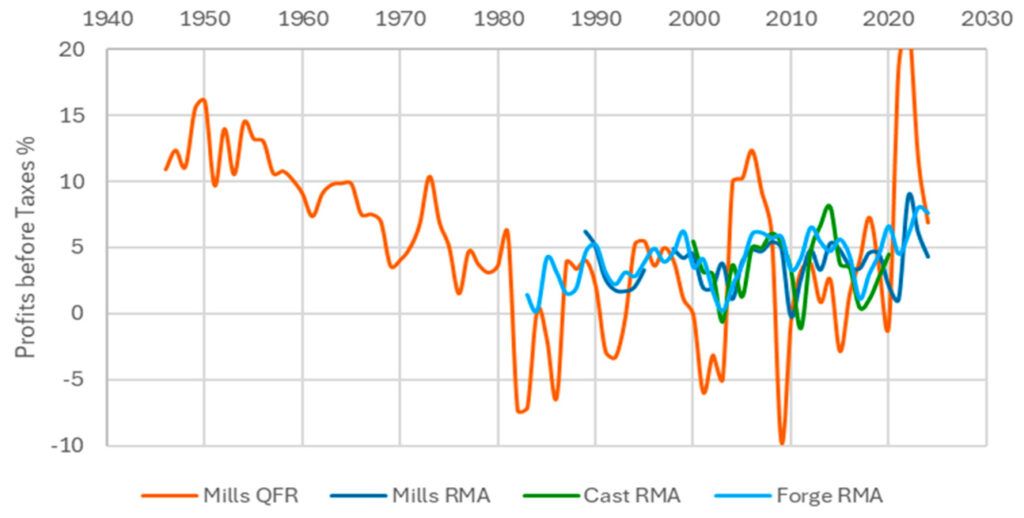

If we look at what these market trends have done to our industries capability to profitably operate and make needed investments in modernization, innovation and automation, it is clear that we have not earned the capital needed. The low profitability since 1980 is seen in Figure 2. How does this level of profitability compared to other industries?

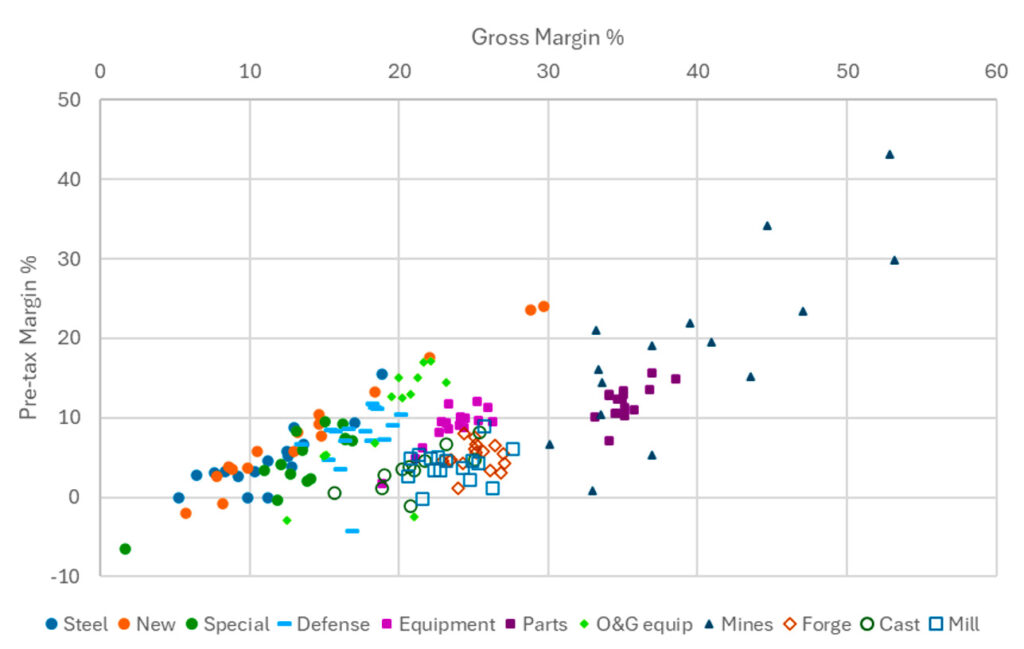

Figure 3 shows that the privately held companies have higher gross margins but similar pre-tax margins. Gross margins is a rough measure of payback periods for capital investment. If the capital investment mainly allows more throughput, then a 3 year payback requires a gross margin of 33%. The pre-tax margin is a measure of how much is available to make the investments.

These graphs and numbers show that we need to concentrate on improving our profitability to ensure we can make the investments needed to provide the products our customers need.

Raymond

Raymond