Castings are seen as a mature and limited technology. There is great excitement in using information technology (IT) and additive manufacturing (AM) to supplement or replace castings. These new technologies are seen as capable of more flexibility, faster production and higher quality than castings. This month’s Casteel Commentary makes the case that IT and AM demonstrate both the historic value of castings and the opportunities in casting today.

Table of Contents

Cast in Steel 2025 Competition

This year is going to be huge, with 47 teams from 32 universities, mentored by 35 industry partners. The competition will take place at Studio Space Atlanta on April 10-11, with the awards ceremony on April 12 at CastExpo, in room A411. Everyone is welcome to attend both the competition and the awards ceremony. Don’t miss it!

SFSA is once again partnering with the Foundry Education Foundation (FEF) for this year’s competition. The Swords will be showcased at the FEF booth during the AFS CastExpo. After the Expo, the Swords will be auctioned off through FEF, with all proceeds going toward FEF’s scholarship program.

Again, this year, our presenting sponsor is the Industrial Base Analysis and Sustainment (IBAS) Program, managed by the Innovation Capabilities and Modernization (ICAM) Office in the Office of the Assistant Secretary of Defense for Industrial Policy (ASD IBP).

| UNIVERSITY | FOUNDRY |

|---|---|

| Arizona State University | ME West Global |

| Baylor University | Tonkawa Foundry |

| California Polytechnic State University, San Luis Obispo | American Casting Company |

| California State Polytechnic University, Pomona | Miller Casting Inc |

| California State Polytechnic University, Pomona | Aerotec Alloys, Inc. |

| California State Polytechnic University, Pomona | Soundcast |

| California State Polytechnic University, Pomona | Jason Gutierrez-SoundCast |

| Central Michigan University | Bay Cast Inc. |

| Colorado School of Mines | Western Foundries |

| École nationale supérieure d'arts et métiers | Safe Metal |

| Georgia Southern University | Georgia Southern University |

| Georgia Southern University (2 Teams) | Carolina Metal Casting |

| Grand Valley State University (2 Teams) | Eagle Alloy Inc. |

| Instituto Tecnológico de Morelia | ACERLAN MATRIX METALS SA DE CV |

| Instituto Tecnológico de Saltillo | Caterpillar Ramos Arizpe |

| Instituto Tecnológico de Saltillo | FAE |

| Iowa State University | Omaha Steel |

| Michigan Technological University | Caterpillar |

| Michigan Technological University (2 Teams) | Temperform |

| Missouri University of Science and Technology | Caterpillar |

| Pennsylvania State University - Erie, The Behrend College | Ashland Foundry |

| Pittsburg State University | Monett Metals |

| Purdue University- West Lafayette (2 Teams) | Kimura Foundry |

| Saint Martin's University | Gil's Foundry & Manufacturing |

| Tennessee Technological University (2 Teams) | Magotteaux |

| Texas State University (2 Teams) | Henderson Manufacturing Company |

| The Ohio State University | Fisher Cast Steel |

| Trine University | Bahr Brothers Mfg. |

| University of Alabama (3 Teams) | Southern Alloy Corporation |

| University of Alabama at Birmingham | Pinson Valley Heat Treating |

| University of California, Irvine | Soundcast |

| University of Dayton | Skuld LLC |

| University of Northern Iowa | TechWorks, UNI Casting Center, American Pattern |

| University of Tennessee Knoxville | TBD |

| University of Wisconsin - Platteville | MetalTek International |

| University of Wisconsin - Madison | MetalTek International |

| Virginia Tech | Dominion Metallurgical |

| Virginia Tech | Midwest Metal Products |

| Wentworth Institute of Technology | DWCLARK |

| Wentworth Institute of Technology | Consolidated Precision Products (CPP Boston) |

| Youngstown State University | Trumbull Metals |

Casting Dreams

Exciting times ahead! Our first round of winners from Milwaukee, Michigan, and Iowa are advancing to the Wisconsin Regional Competition, which was held at the AFS Wisconsin Chapter Regional Foundry Conference & Expo at the beginning of this month. Since January 1st, over 500 students all over the US are hard at work, pouring their castings and hoping to move on to regionals.

The National Competition will take place on Monday, April 14, at 3:00 PM at the AFS HUB during CastExpo in Atlanta, Georgia. Don’t miss the chance to see the incredible castings these talented young students have created.

NASCC and Nucor Tour

The building construction conference, NASCC, will be April 2-4 in Louisville, KY. SFSA’s partnership with AISC, has enabled the use of steel castings for North American buildings to no longer be a novelty, but more opportunity for our industry awaits. This year marks several achievements and near-term accomplishments:

- SCI structural steel castings design guide

- Castings included as a product form in AWS D1.1 including ASTM A216 WCB and WCC as prequalified based metals

- University of Arizona design and welding steel casting research for building construction

- AASHTO/NSBA resources for using steel castings in bridges

- Draft AISC steel casting design guide

Members can receive an exhibit pass for Thursday 4/3 and tour Nucor – Gallatin on Friday 4/4. Only 18 registrants may attend. RSVP with Dave by February 21.

78th Technical & Operating Conference

The T&O this past December was another success thanks to the authors, workshop presenters and T&O Committee. With an incredible 70 papers presented mostly by member foundries, it was a tremendous opportunity to work together to advance our industry. We all benefit from foundry members, academic partners, and government personnel who come together to make our industry better. Planning is already underway for this year’s conference; tentatively scheduled for December 10-13 in Chicago. If you would like to recommend a topic and presenter for the 79th T&O, please contact Dave.

Research Review, July 8-10

Please make your plans to participate in the annual SFSA Research Review on July 8-10. This year’s meeting will be held in-person in Rosemont, IL. The Review covers the latest in both Carbon & Low Alloy and High Alloy steel casting research under the AMC and STAR programs. The meeting is also your opportunity to interact with the researchers and provide industry steering. The event vets our research portfolio to select the R&D projects to be featured at the National T&O. More details regarding registration and the Design Day are to come. For any questions, contact Caelan Kennedy (ckennedy@sfsa.org).

POK Foundry Closing

Nucor subsidiary POK will be closing both plants in Mexico this month. Nucor is currently seeking interested buyers. For more information, contact Gustavo Fuentes, gustavo.fuentes@pok.com.mx.

Some of the foundry’s personnel has expressed an interest in relocating to work in a US foundry. SFSA will post resumes on the website and notify members of updates. The first resume has been posted to https://www.sfsa.org/graduates/.

Market News

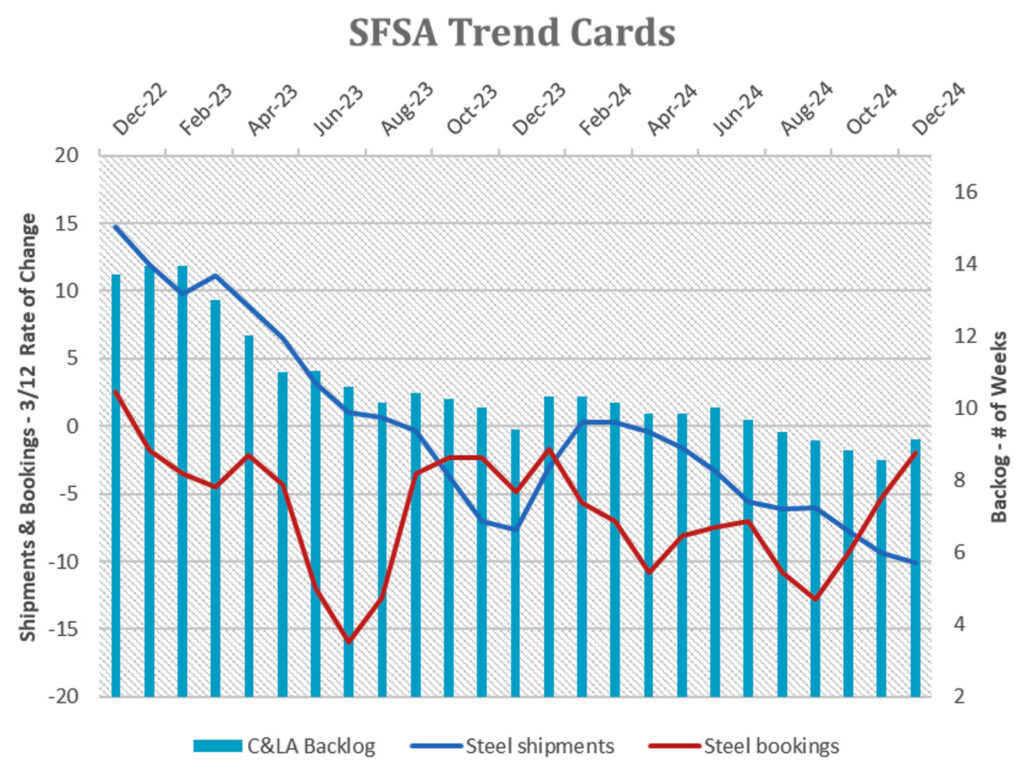

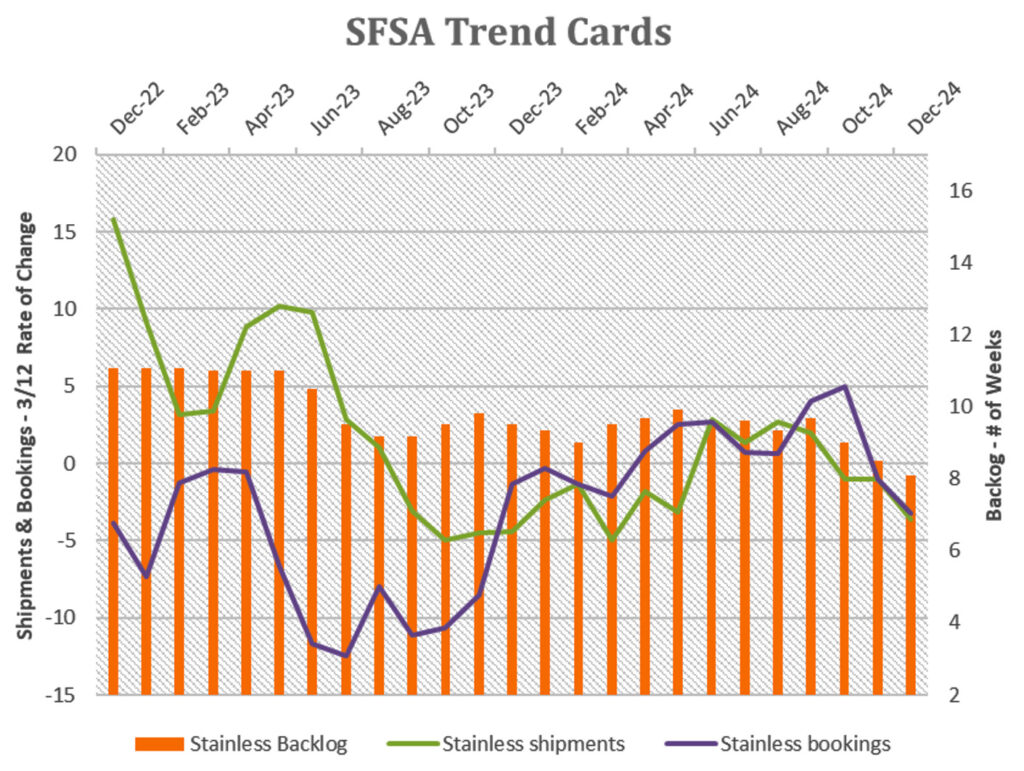

In December, stainless bookings and shipments finished out the year just below 2023 levels. Steel casting bookings continue at an upward trend from its September low while steel casting shipments continue a downward trend to 10% below year ago levels. Carbon and low alloy steel backlog increased from -15% YoY to -3%. Stainless backlog decreased slightly from -14% YoY to -15%.

ITR reports that this year many manufacturing markets will experience growth as strong corporate profits and resilient consumer demand drive increased production. While growth may be modest in the first half of the year, most markets are expected to surpass 2024 levels by year-end. Expansion will continue into 2026, with the majority of markets entering Phase C, Slowing Growth. By 2027, the manufacturing sector will largely stabilize, with growth rates hovering slightly above or below zero, resulting in a mixed year-end outlook.

| STEEL FOUNDERS' SOCIETY OF AMERICA BUSINESS REPORT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SFSA Trend Cards (%-12 mos. Ago) | 12 Mo Avg | 3 Mo Avg | December | November | October | |||||

| Carbon & Low Alloy | ||||||||||

| Shipments | -4.8 | -10.1 | -12.3 | -8 | -10 | |||||

| Bookings | -7.3 | -2 | -3 | -3 | 0 | |||||

| Backlog (wks) | 9.6 | 9.1 | 10 | 8.3 | 9.2 | |||||

| High Alloy | ||||||||||

| Shipments | -1 | -3.7 | -10 | 5 | -6 | |||||

| Bookings | 0.3 | -3.2 | 3.3 | -16 | 3 | |||||

| Backlog (wks) | 9.2 | 8.1 | 8.8 | 7.5 | 8 | |||||

| Department of Commerce Census Data | ||||||||||

| Iron & Steel Foundries (million $) | ||||||||||

| Shipments | 1,656.60 | 1,677.30 | 1,688 | 1,698 | 1,646 | |||||

| New Orders | 1,681.70 | 1,780.70 | 1,793 | 1,846 | 1,703 | |||||

| Inventories | 3,269.80 | 3,388.00 | 3,419 | 3,375 | 3,370 | |||||

| Nondefense Capital Goods (billion $) | ||||||||||

| Shipments | 83.4 | 83.2 | 84.8 | 82 | 82.8 | |||||

| New Orders | 83.5 | 83.5 | 78 | 84.8 | 87.6 | |||||

| Inventories | 231.7 | 232.4 | 234 | 232.5 | 230.8 | |||||

| Nondefense Capital Goods less Aircraft (billion $) | ||||||||||

| Shipments | 74 | 74 | 74.3 | 74 | 73.8 | |||||

| New Orders | 73.8 | 74.3 | 74.7 | 74.4 | 73.8 | |||||

| Inventories | 163.1 | 163.4 | 163.5 | 163.6 | 163.3 | |||||

| Inventory/Orders | 2.2 | 2.2 | 2.19 | 2.2 | 2.21 | |||||

| Inventory/Shipments | 0 | 2.2 | 2.2 | 2.21 | 2.21 | |||||

| Orders/Shipments | 0 | 1 | 1 | 1.01 | 1 | |||||

| American Iron and Steel Institute | ||||||||||

| Raw Steel Shipments (million net tons) | 7.2 | 6.9 | 7.1 | 6.7 | 7 | |||||

Casteel Commentary

Steel Castings and the use of IT and AM

Information technology (IT) is a set of related fields that encompass computer systems, software, programming languages, data and information processing, and storage. (https://en.wikipedia.org/wiki/Information_technology) One way to characterize even pre-computer materials and components is to think about how smart they are. An example could be looking at modern steel materials. Most mill products have only a few characteristic geometric measurements that define the product. A bar is defined by the diameter, a plate by the width and thickness. So a plate is “smarter” has more geometry or dimensions that define it. A bar can be made smarter by cutting it to length and then it has both diameter and length. A plate can also be cut to length but could be cut to any shape like making a cookie. A plate can be much smarter with a 2D shape cut out. Castings are a smart technology since geometry is the characteristic advantage of using castings. We sell geometry.

Prior to industrialization and the making of standard products, each part had to be taught by the artisan craftsman individually to be smart enough to work. The smartness of each piece was created by the maker. One of the advantages of industrialization was the mass production of relatively dumb materials that could be processed to be smart enough to become the part needed. The geometry or information embedded in the part relied on the manufacturing process to become smart enough to function.

Casting were the earliest and were always smart technology. While they provided metal materials for challenging performance, their key benefit was geometry. Castings with cores could provide geometries unobtainable from other methods. Castings historically had another information technology like advantage. The information or smartness of the geometry was not dependent on the artisan producer but installed in the tooling. Since the development of sand casting using patterns and cores over 2500 years ago, castings could be produced to unique geometries from tools that contained the geometric information required for the part.[1] In this sense, metal casting was an early information technology.

Steel castings benefitted from this value and castings were the high value steel product, making available the shape, the geometry, required for parts. Many steel parts could not be made any other way.

To facilitate the quality required and support the performance needed, steel castings were early adopters of AM. Welding on steel castings as a part of ordinary production has been part of the industry for over 100 years. Steel casting producers were early users of arc welding to replace non-compliant parts of the casting and re-create the feature geometry and provide performance required.

Since welding was new and fabrication welds were repaired when cracked, the industry adopted the high tech terminology used for remediation of fabrication welds and called this AM process repair welding. If we used today’s terminology, steel castings were early adopters of direct energy deposition (DED) using AM to create the critical features for casting after removing non-compliant material. The terminology for welding has been changed in many specifications from repair welding to production welding to highlight the normal use of AM DED to complete the production of steel castings. Specifications for critical steel castings for production welding are over 50 years old with the ASME BPVC Section 9 being issued first in 1958.

3D printing for AM is a huge advantage for steel casting producers. Since casting production tooling with complex geometries is essential, 3D printing was adopted early by steel casting producers for fabricating tooling. Fast Free Form Fabrication (FFFF) identified Laminated Object Manufacturing (LOM) as a way to produce 3D printed pattern tooling since 1990. Printing steel parts with AM needs to develop properties and quality requirements to ensure reliable service. Steel casting producers had the benefit in utilizing AM for tooling so that they could produce technically compliant castings to current specifications using tooling produced by AM.

AM for pattern tooling or for investment castings allows a direct way to turn new designs into castings without the delay or full cost of tooling. The introduction of sand printing for cores and molds made 3D printing and AM technology available for more steel castings. This is giving steel casting designers, users and producers substantial benefits.

AM in the training and development of designers moves them from creating their parts from fabrication using standard shapes to allowing the product requirements to identify the geometry and features needed. For casting producers, allowing the part requirements to determine the geometry makes designs better suited for casting production. The same section transitions, radiuses, non-uniform sections, internal geometries that are characteristic of 3D printed shapes are ideal for casting.

Parts of limited production with an aggressive schedule may not have considered using castings because the cost and time involved in prototyping. Printing the mold for prototype production not only resolves the schedule and cost barrier but it also allows parallel design concepts to be explored without the sunk cost of multiple tooling options. This encourages designers to not only make ordinary evolutionary modifications but it also allows alternative radical concepts to be explored economically and quickly.

AM produced castings have the ordinary and understood properties of steel castings and require no new design approach or NDT quality development. It also allows the ability when production volumes are considered to move to hard tooling and increase the volume production required at a desirable cost.

Many are intrigued with the replacement of castings with AM. There are advantages of AM and unique situations where that may be attractive. In some remote locations AM could eliminate the need for voluminous spare parts and allow innovative parts to be made. In some high-performance critical applications, constitutionally grades components, components that need one end made from one material, like copper for conductivity, transitioning to another material like a tool steel H13 for hardness and elevated temperature properties. These special products can be made by AM laser powder bed fusion (LPBF).

There are places where the cost and production size and rate constraints of AM are not problematic, and the lack of developed properties and NDT is not problematic. The excitement of AM though can mislead and the cost for AM will always be problematic.

To produce a part from AM, the steel is bought as wire or powder. The cost of the powder or wire is no less than the cost per pound of the material. For powder it is much more, maybe 4 times as much as the alloy itself costs, so LBPF is expensive and relatively slow. The cost of the wire for DED is about the same as the mill product but the cost of remelting and depositing would double the cost of the material before the cost of finishing and inspection.

There is no clear way for any significant production where the cost of the material is driving the economics for DED or LPBF to be less expensive. You cannot melt steel and turn it into wire or powder and then remelt it to make the part and be less expensive than casting the part in one melting step.

As parts become larger, this cost challenge grows.

AM is a great benefit to us in steel castings. We were an original information technology and our ability to create geometry becomes more important as AM leads designers to complex geometries for higher performance. Our ability to use AM for tooling or molds allows us to eliminate the need for tooling in product development. Eliminating the cost and time for tooling in product development allows potential casting users to explore more design alternatives prior to tooling or eliminate the need for tooling if quantities are low. Quality requirements for the range of services are developed for casting and design properties are available. These are still under development in AM produced metal parts. The inherent cost of AM that depends on quality feed stock will limit the ability to be cost effective and limit the range of materials that can be utilized.

On balance, IT and AM makes the case for steel castings as a needed valuable and capable production method for many of the critical components needed for our growing investment in manufacturing and infrastructure.

[1] Kurkul, “Revisiting Metalcasting’s Fascinating History.”

Raymond