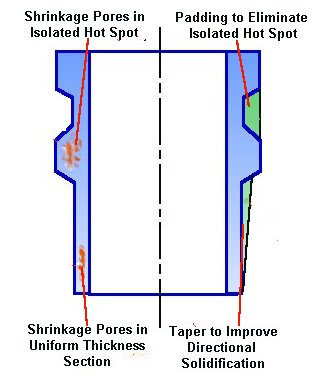

| Eliminate

or Reduce Isolated Hot Spots In

evaluating a component design, the casting engineer looks for isolated thick sections

which could be "hot spots" where shrinkage porosity or "hot tears"

might form.

- As metal in thin sections solidifies first, the

thicker section will be isolated from the molten metal feed and shrinkage porosity can

form in the thick section .

- The thin connecting section into the thicker section

should be "padded" to improve the thermal connection and metal flow into the

"hot spot".

Directional Solidification

The casting engineer studies the design to see if the

thermal gradients in the piece will promote directional solidification. Review the

design, looking for flat sections that can be lightened and long thin ribs that need to be

tapered to promote directional solidification

- Large flat sections are difficult to feed and to

develop good directional solidification. Adding taper along a rib or section from the cold

region to the hot region promotes directional solidification and prevents shrinkage pores.

|

Generic Example of Padding and Taper

|